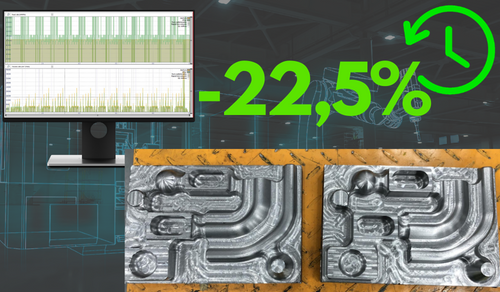

Machining time reduced by 22,5% and perfect surface quality of the worked pieces.

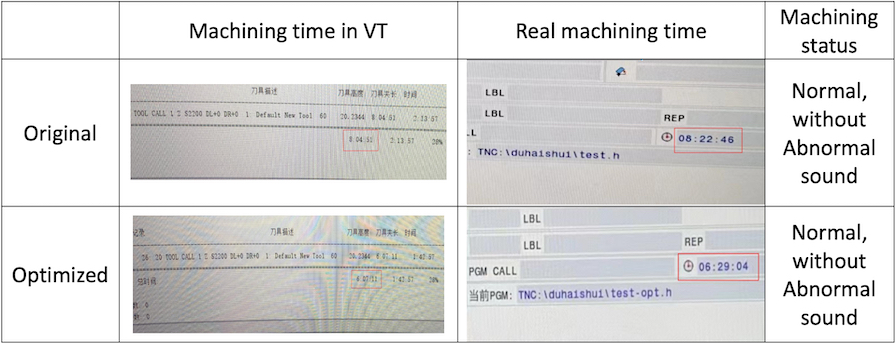

A new customer decided to test Eureka Chronos by comparing two works of the same piece. The first processing was carried out with the original NC program, while the second with the optimized NC program.

PROCESSING DETAILS

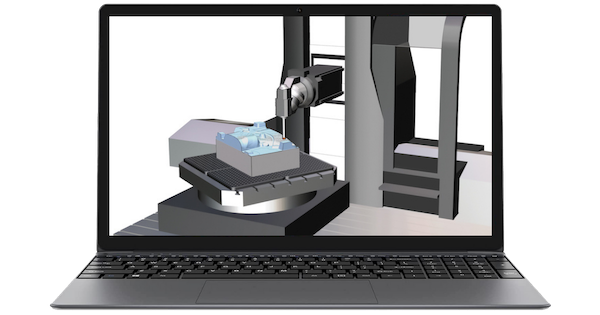

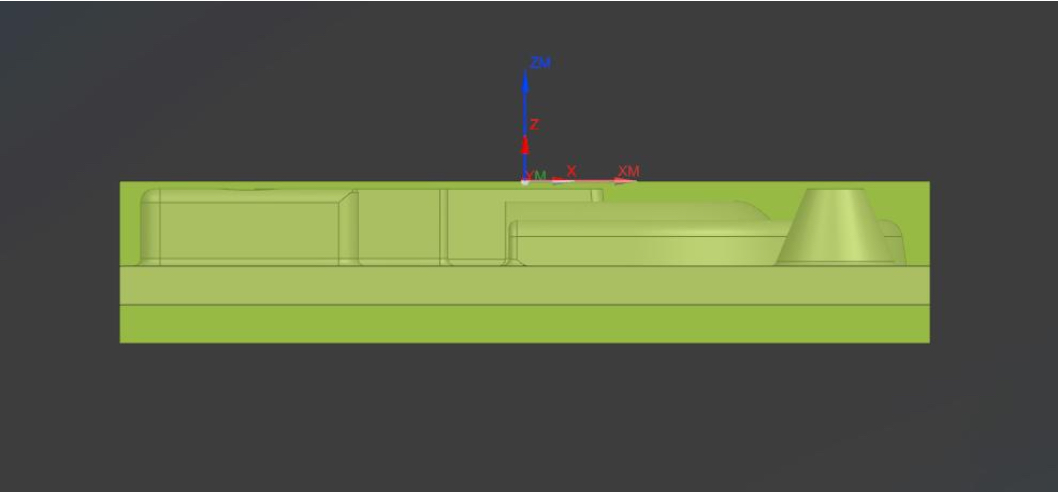

Material: steel, size 210*142*42mm (2 pieces)

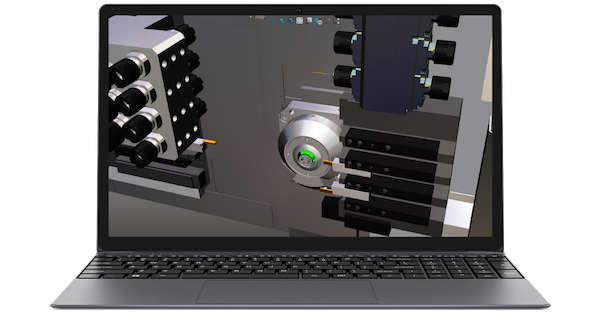

Roughing with tool D16*R3*30*120L*4F, cutting depth 0.3mm, cutting width 9mm, feedrate speed F800/S2500

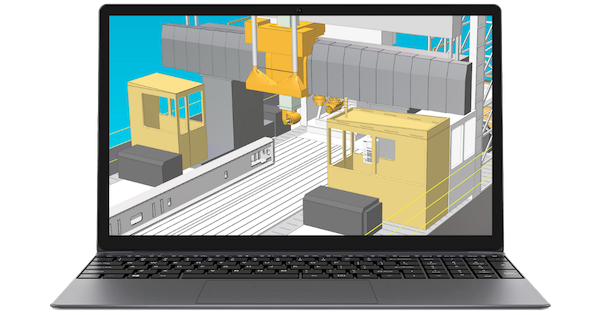

Machine tool GF P800U

RESULTS:

Same surface quality of parts

Machining time is reduced from 8 hours and 22 minutes to 6 hours and 29 minutes: 22.5% time saved.